GUIDANCE FOR FUSING TESTS

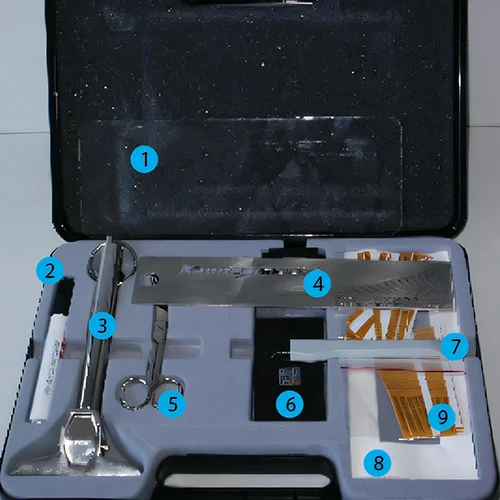

Test set box

FUSING TESTS

Testing boxes are avaliable on stock! Do not hesitate to ask for the offer!

Today’s fabric and interlining is very sensitive to heat and pressure. If the fusing machine is not in a good condition or fusing conditions are not according to the interlining specification, a lot of problems can be created.

Fusing was and still is a very delicate operation within the garment manufacturing process. If any problem arises, it has to be eliminated immediately, as problems easily can be multiplied.

The Test Set is made to assist you in checking your fusing machine and fusing goods by clear results.

It was made for day to day use on the production floor in cooperation with most of the major interlining suppliers.

TEST SET

1. Cutting plate

2. Marker

3. Bond Tester

4. Shrinkage Roller

5. Scissors

6. Tape

7. Knife

8. Paper Frames

9. Temperature Strips

Glue Line Temperature

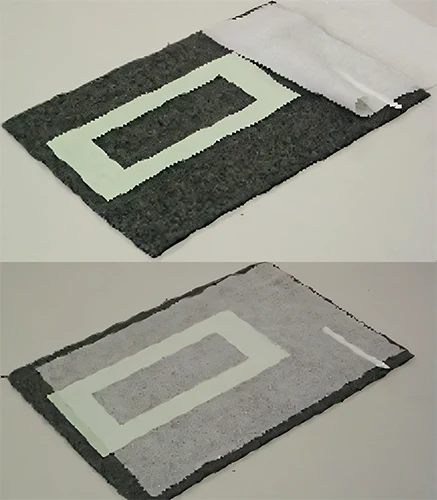

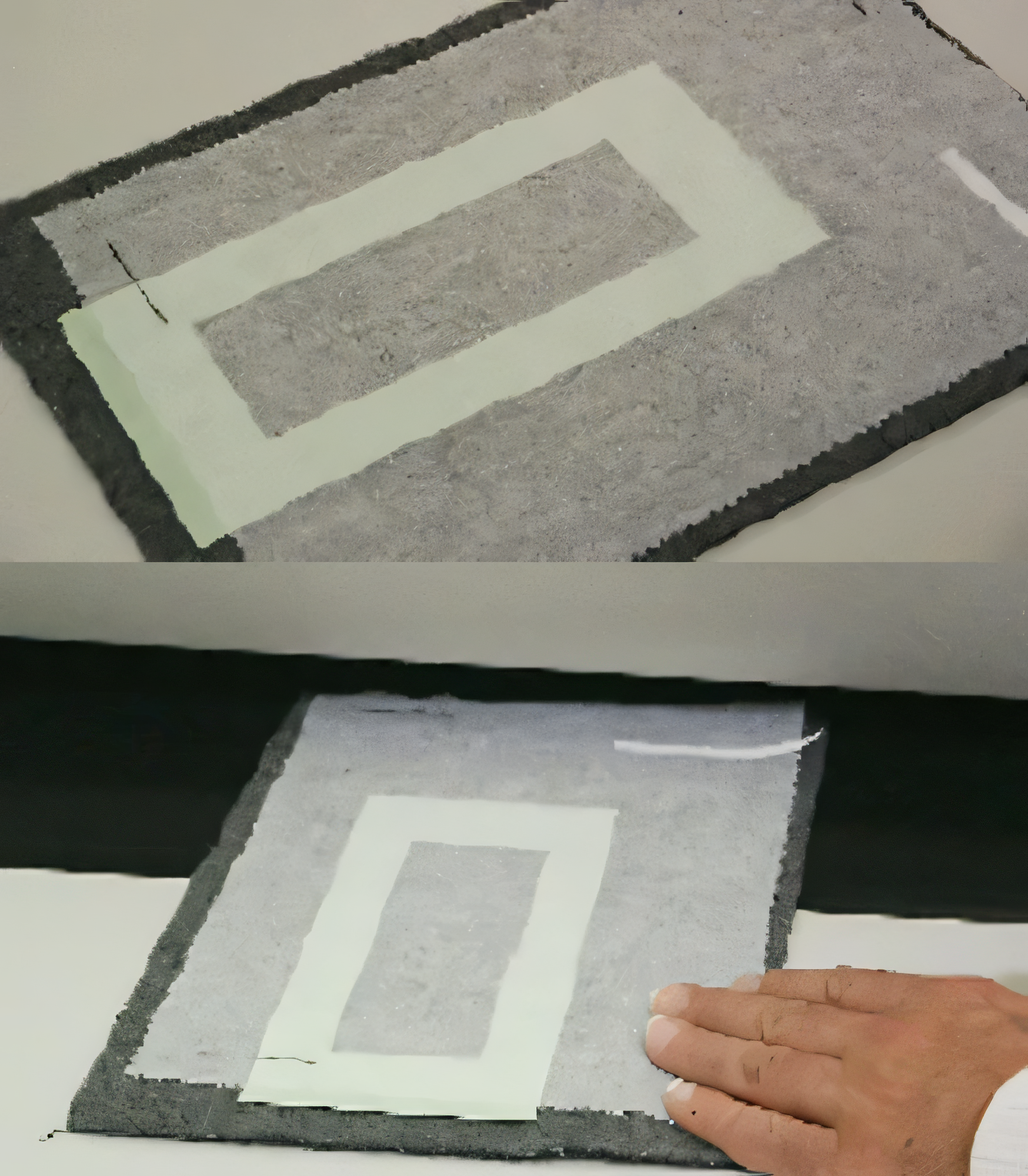

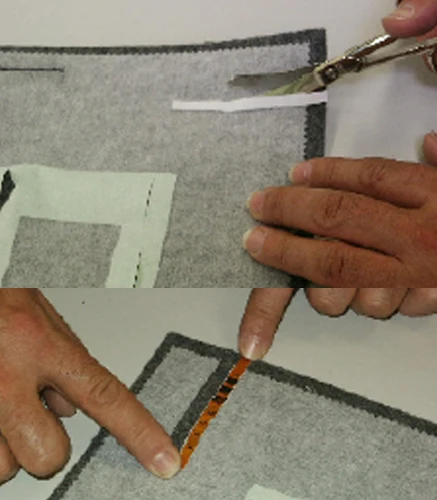

Choose interlining and shell fabric to fuse. To prepare the sample for the bond test, place interlining with the glue facing down.

Place temperature strips face down in between interlining and shell fabric.

Note: Adjust those temperatures on the display indicated on the strips.

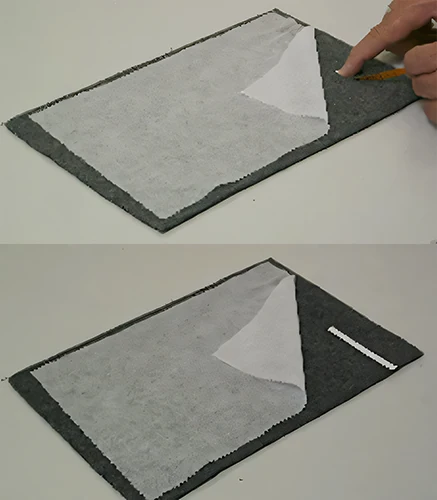

Bonding Test

Place the paper frames in between the interlining and the shell fabric. Leave the top side of the paper frame out.

In case paper frames are not available, use the shrinkage roller to cut a 50 mm wide strip into the sample.

Shrinkage Test

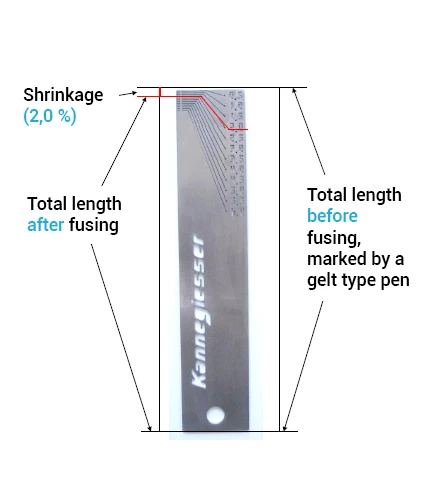

Use a small felt type pen to mark both ends of the shrinkage roller, or cut both ends of the roller with a knife.

After preparation, a clear mark should be visible.

Put the sample into the machine

Shrinkage Test

Place the shrinkage roller on the fusing sample after fusing. Make sure the roller matches the mark on one side, so that the shrinkage rate can be read on the other side.

Shrinkage Test

How to read the shrinkage rate?

Bonding Test

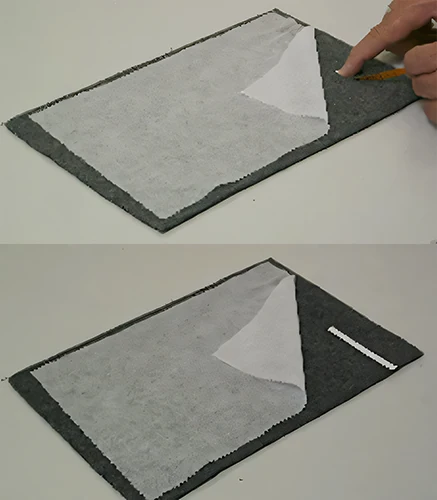

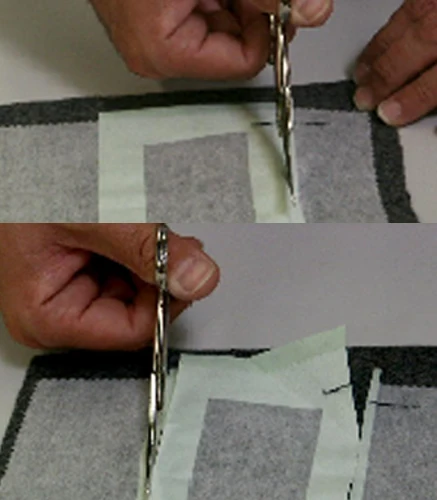

Cut paper frame and interlining on one side.

Then on the other side.

Put interlining and paper frame into the jaws of the bonding tester. Jaws and paper frame should be absolutely parallel. Watch your fingers.

Hold the shell fabric with one hand and pull gently and straight the bonding tester with the other hand. Make sure you don`t pull too fast. Observe the scale and read the bond strength from the scale (Newton).

Note:

1kg = 10 N = 1 kp

The complete test can also be done to check the left, centre and right side of the machine.

Glue Line Temperature

To check the glue line temperature, cut the temperature strip on one side.

Note: Never leave temperature strips in a hot place. Keep them cool and dry.

Read the glue line temperature above the black field. If a field is not black, but shows any grey colour, the temperature is somewhere in between two temperature indications.

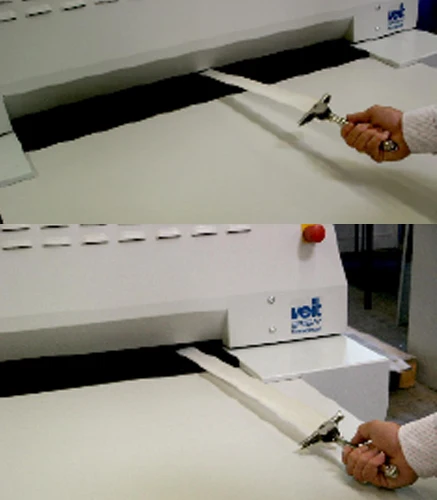

Pressure Evenness

Turn the pressure down to about 2 bar pressure.

Use the tape in your test kit and put it into the claw of the bonding tester. Let the tape go into the machine completely and read the value from the scale. Hold the tape straight. Do the same on the left, centre and right side of the machine.. The allowance from the left to the right side should be within 20 % from the total value. Make sure that the distance between the bonding tester and the belt is always the same.

Note: This test can only be done on a clean and relatively new belt. The fusing machine belt must be cold.

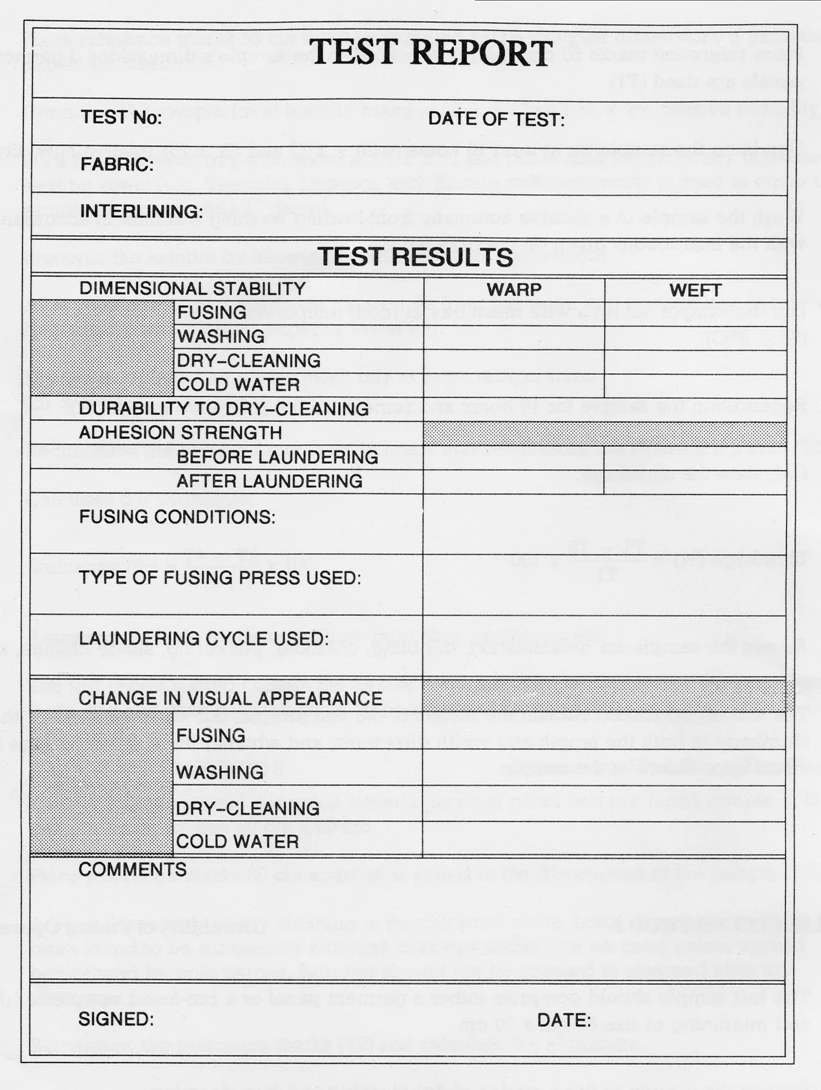

Beside the fusing test itself, the test result has to be noted in a report and should be stored for later use or as proof of correct fusing.

The documentation should show the following details:

- Set temperature, top heat zone

- Set temperature, bottom heat zone

- Glue line temperature

- Set pressure (for one or two pressure systems)

- Set speed (in seconds)

- Bond strength after fusing, in Newton

- Shrinkage after fusing, in Percentage

- Any special characteristic of the shell fabric and/or interlining.

- Any change of characteristic after fusing, like shading effects, discolouration, flatness etc.

- Stick a sample of the shell fabric and the interlining to the data sheet.

For further tests, like washing or dry cleaning tests use the following form sheet as a reference.